Tech Tip #2: Equivalent Lengths

Proper airflow distribution is critical to the performance of residential forced air heating and cooling systems. Sheet metal pipe, duct, and all the connecting fittings are produced in many sizes and styles to enable the contractor to make the proper installation in all types of residences.

What is “Equivalent Length”?

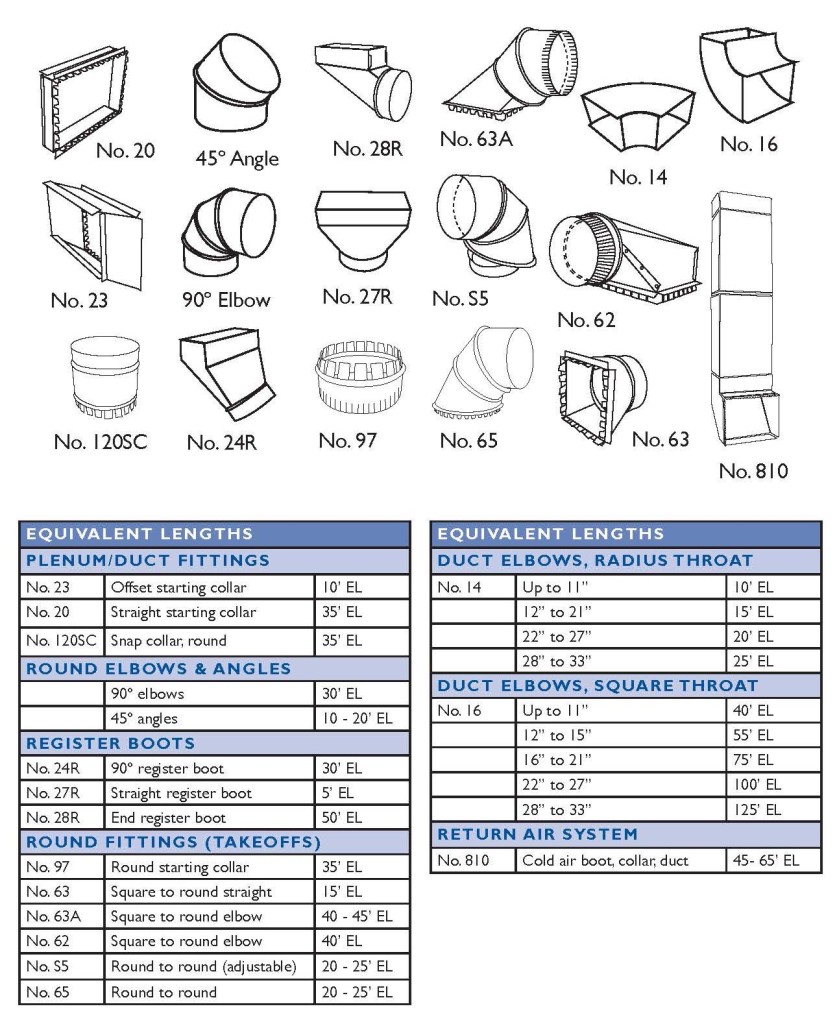

Each type, style, and configuration of fittings (elbow, angle, takeoff, reducer, diffuser outlet, register boot, etc.) is listed in ACCA’s Manual D with an assigned “equivalent length.” This value is the comparison “length” of this fitting to an equivalent length of straight pipe or duct. For example, each elbow used is equivalent to 30 feet of straight pipe or duct.

Southwark Metal Mfg’s sheet metal pipe, ductwork, and fittings conform to this system of equivalent lengths as well as conforming to industry national standards for describing residential fittings.

Why are Equivalent Lengths Important?

Equivalent lengths become important to the HVAC system designer who is looking to ensure proper airflow distribution with the “Equal Friction Method” of duct sizing. The sum of all equivalent lengths of fittings used and the measured distances of all pipe and duct from room terminal to the air handler should be calculated for each conditioned room. The two largest values, i.e. the longest supply and the longest return runs, are added together to create a total called “the critical path.”

[Available Static Pressure (ASP) x 100] divided by [Critical Path (in feet)] = Design Factor

The design factor, calculated from the above formula, and the required airflow (CFM) are then used in a duct calculator to determine the size of all supply and return duct.

Note: The Duct Design Center presents tips and information for general approximations only. All local codes and manufacturer’s instructions should be taken into account first and foremost when designing a distribution system.